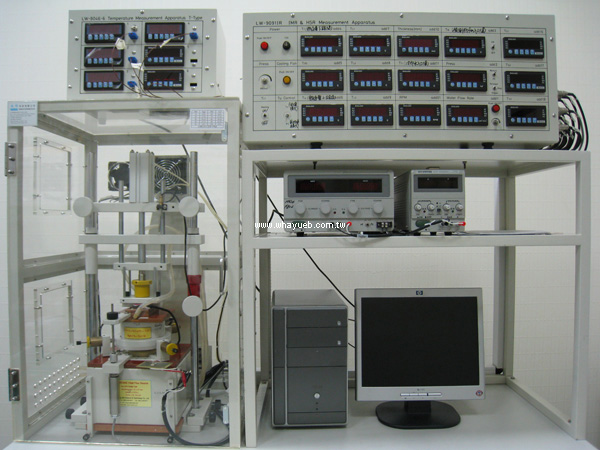

Production & Quality

Wha-Yueb Technology Co., Ltd. is a high-tech enterprise dedicated to the development, manufacturing and marketing of high performance thermal interface materials over the past decade. We have maturity production line and strict quality control to provide you reliable products.

Thermal pad production process

Mixing the formula

- Mixing the silicone & Filler in accordance with SOP

- Grinding process

Molding by high temperature process

- Molding and forming with semi-finished mixing formula by parameters

- Secondary sulfur

Extra processes

- Provide the adhesive tape depending on the customer needs

- Rewinding the adhesive tape and cutting process

Final Inspection and shipping

- QC do the inspection for the size and shipping to the customer according to the packing specification

Thermal tape production process

Formula mixing

- The encoded glue and filler will be mix by the specified parameters in accordance with SOP

Coating

- Coating with glue in specific thickness

Crosslinking

- Actives the glues to films

Rolling

- Winding the films to the shape in roll

Forming

- Placing the roll tape in fixed temperature and humidity

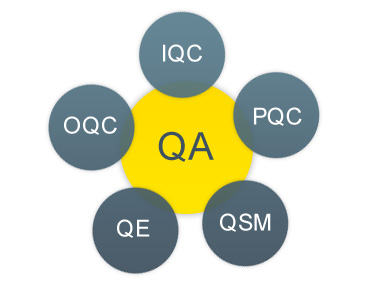

Quality system

| IQC |

|

|---|---|

| PQC |

|

| QSM |

|

| QE |

|

| OQE |

|